1. The production process of good metal carved board is strict and the cost is high

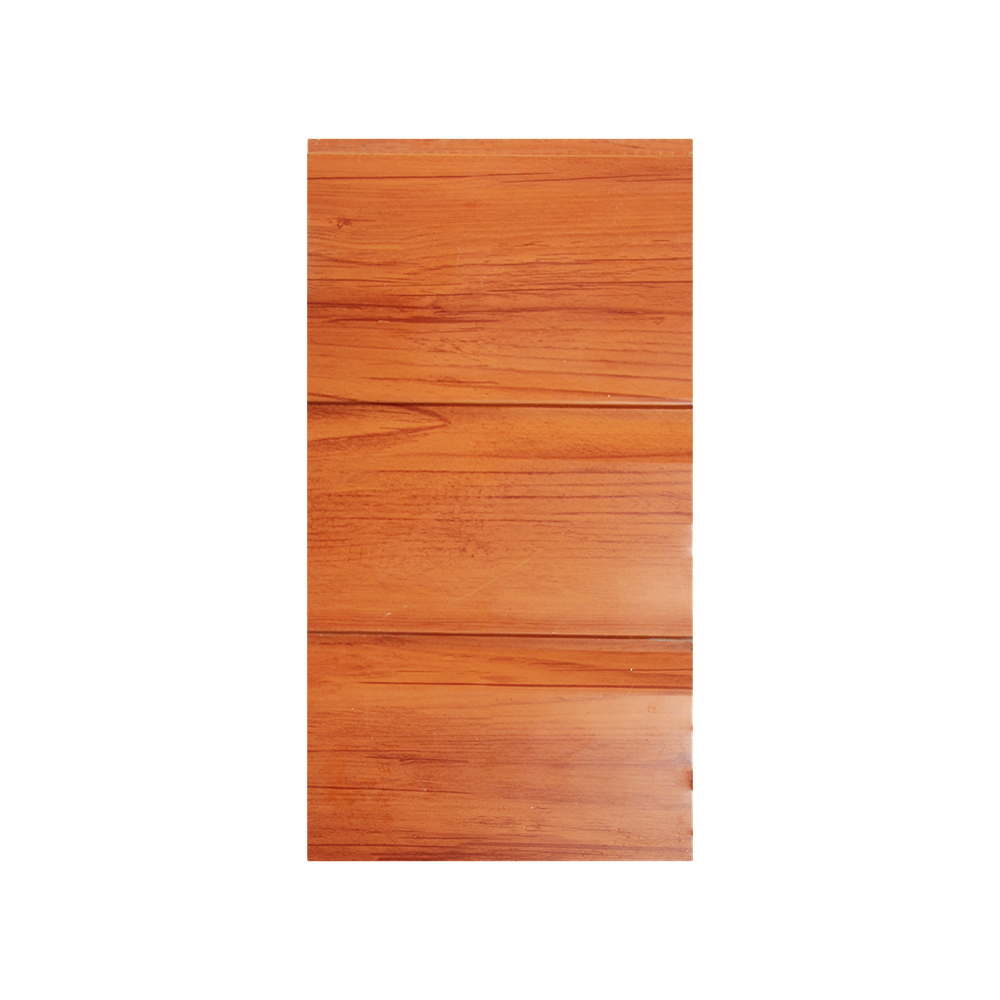

Metal carved boards require special processing and are manufactured through dozens of demanding processes. Good metal carved boards use high standards of raw materials:

The aluminum zinc coated steel plate contains 50-100g of aluminum zinc. The aluminum zinc alloy structure of the aluminum zinc coated steel plate is composed of 55% aluminum, 43.4% zinc, and 1.6% silicon solidified at 600 ℃. The entire structure is composed of aluminum zinc silicon iron, forming a dense quaternary crystal, thereby forming a strong and effective barrier to prevent corrosion factors from penetrating.

A good metal carved board has a higher cost, so it is more expensive!

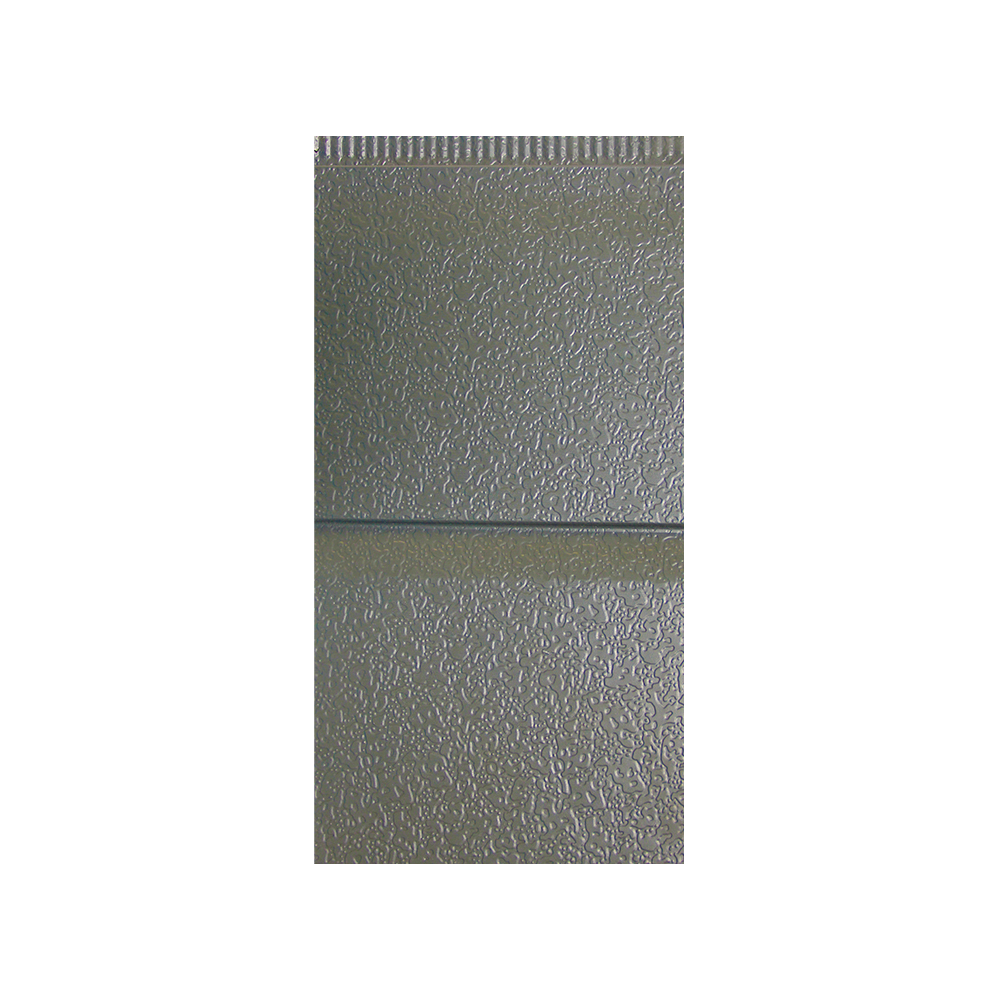

2. Good metal carved boards have strict inspection standards and are eliminated as unqualified

Metal carved boards produced with high standard raw materials will not exhibit surface bulging, structural cracks, discoloration, or substandard fire resistance. The selection standards for good metal carved boards are stricter than national standards, and unqualified products need to be eliminated.

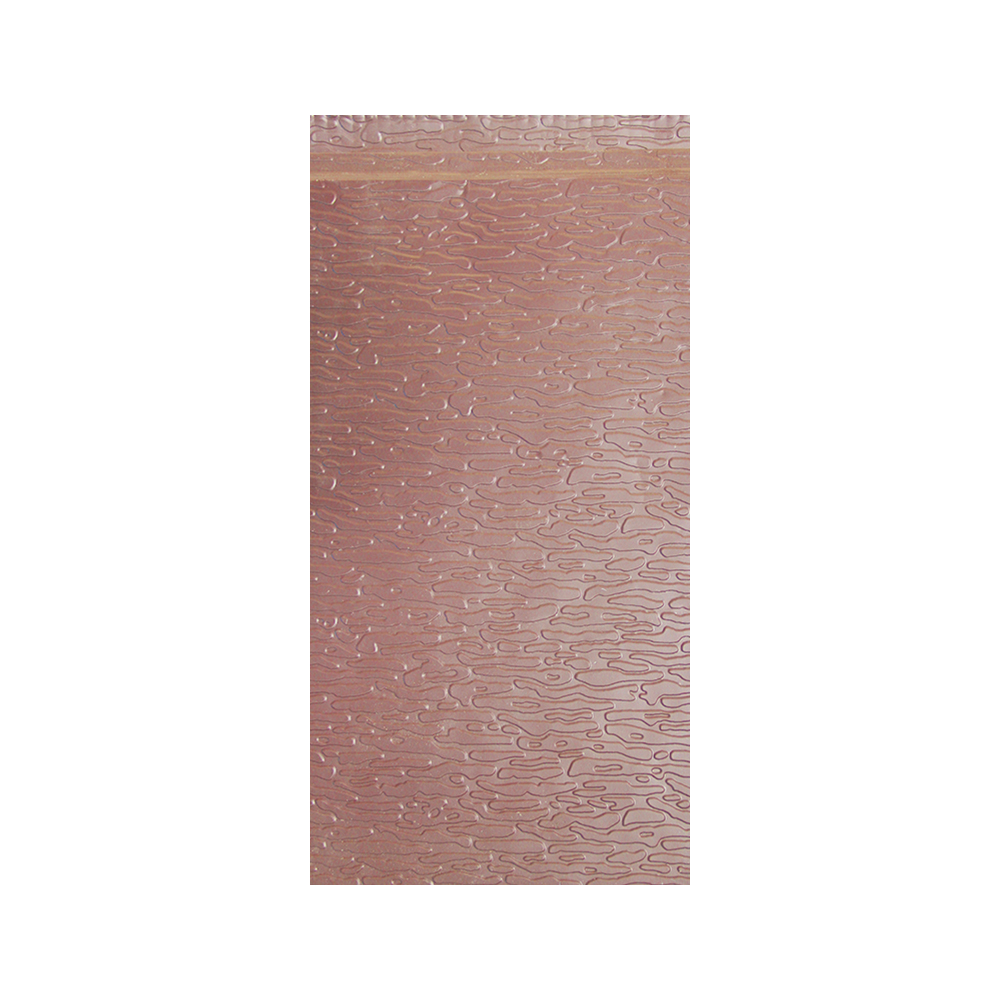

3. Good metal carved boards are not only good products, but also good services